The Company

VR Group has been developing and manufacturing molds for diverse industrial uses for many decades. The Company was founded due to the need of VR group to have a plant dedicated to the production of molds used in VR’s production lines, making headlamps for the automotive industry initially and subsequently door glass for washing machines.

In the mid 1990’s, as design became more and more important it was necessary, especially for headlamps, to move from glass to plastic products as the latter gave more flexibility as far as shape was concerned. VR Group therefore began to produce molds for termoplastic materials and created an inhouse sampling plant for injection pressing to verify the goods their molds were producing.

To date, VR Group has produced almost 1000 molds for the most important customers on the global stage. The structure of the plant, the experience and the qualified personnel all permit VR Group to work closely with the customer, from the preliminary development and design stages of the car components through simultaneous engineering, up to the final sampling of the mold on the pressing equipment.

The principal clients of VR Group in the automotive sector are: Marelli, Valeo, Farba, ZKW, Koito, Elba, Magna, Optrel, Wide Eye, Hella.

VR Group is able to design and develop injection multicolour molds for thermoplastic materials, molds for thermosetting plastics and those for multi-components i.e. plastic /rubber. In 2012 VR Group purchased a new 1700 ton press to sample the requested molds entitrely in house, to meet the customer’s needs for taylor-made components, i.e. bicolour and tricolour products.

VR Group is experienced in the development of the full range of lighting components for head lamps and rear lamps: principal & internal lenses, principal and secondary frames, housings, light guides, reflectors in BMC.

In the <testimonials> section you will find a display of recently developed products that are already in use on the market, all made using VR group molds.

| Headlamp | Rearlamp |

| Mono/bicolour & tricolour lenses | Mono/bicolour & tricolour lenses |

| Mono/bi & tricolour frames | Mono/bi & tricolour frames |

| Housings | Housings |

| Light guides | Light guides |

| Reflectors in BMC |

Our products

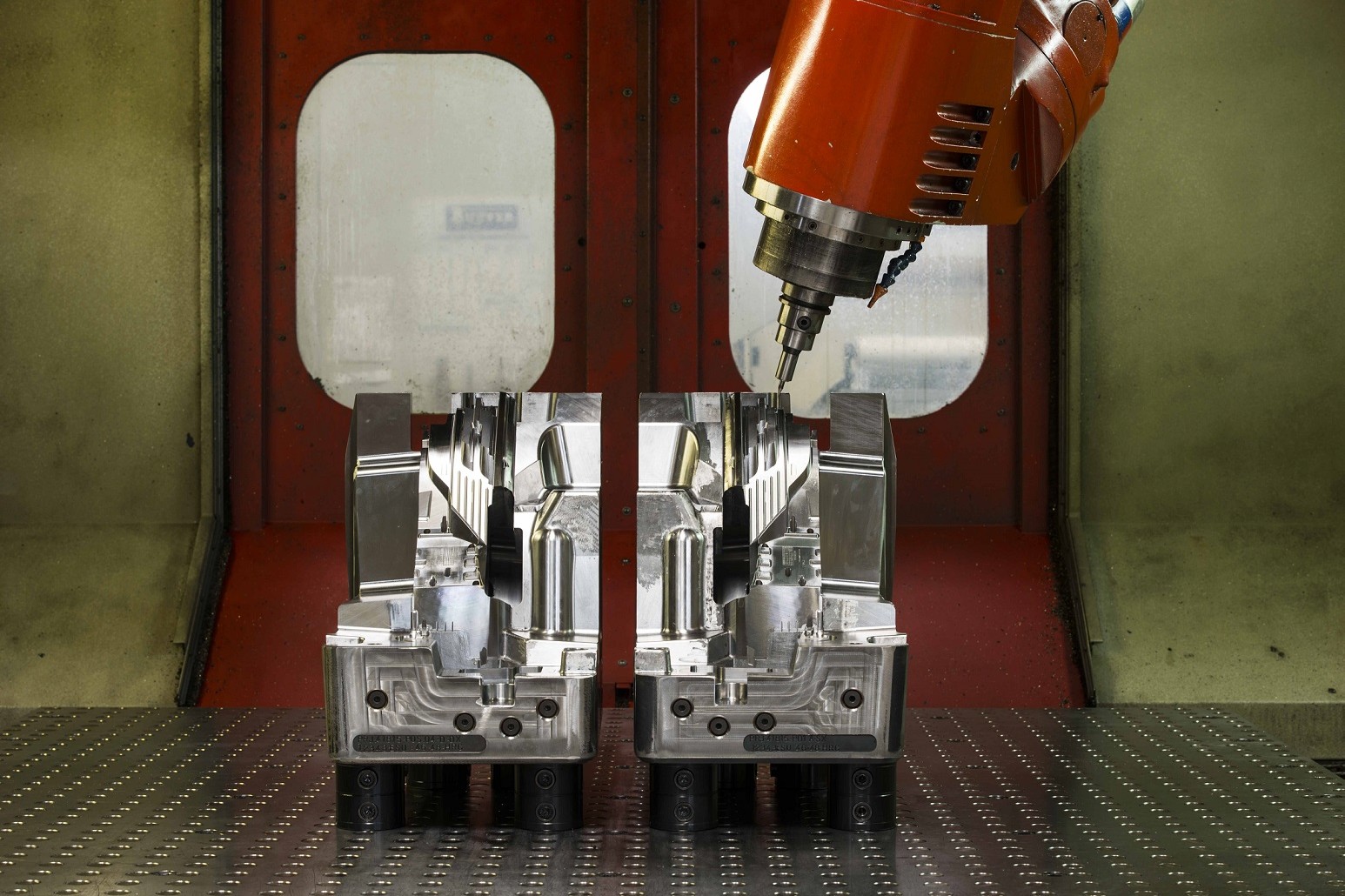

Plastic molds

VR Group builds molds in steel to produce plastic components for the automotive sector. High precision molds with surfaces polished like a mirror are the details that provide the perfect mix to create products by VR group. We can also produce molds with up to three verying materials and up to three individual colours.

Glass molds

Production of high precision molds to create highly detailed glass products. Thanks to a special system it is possible to create an infinite variety of products with very complex shapes and we can even personalise down to a single mold for one off items

Quality

The quality system at the business unit Borromini by VR group plant has been certified in accordance with ISO 9001 since 2002. This has allowed the continuous and constant monitoring of the plant, in line with the company mission statement, to guarantee to the final customer; strict respect for procedures, traceability and constant improvement of the management/production processes.

Technology & Innovation

The production process of the molds is highly integrated as all the principal phases are entirely managed internally. There are 9 work stations equipped with CAD Catia and Unigraphics utilized for mold development and Moldflow software to study rheology.

As regards machine tools, these are produced using WorkNC software.

Production comprises 15 machine tools, including the recent addition of the Huron VX18, 6,000 g/min, 3 axle milling machine and FTD Stinger 280, 18,000 g/min 5 axle finishing machine in line and palletized.

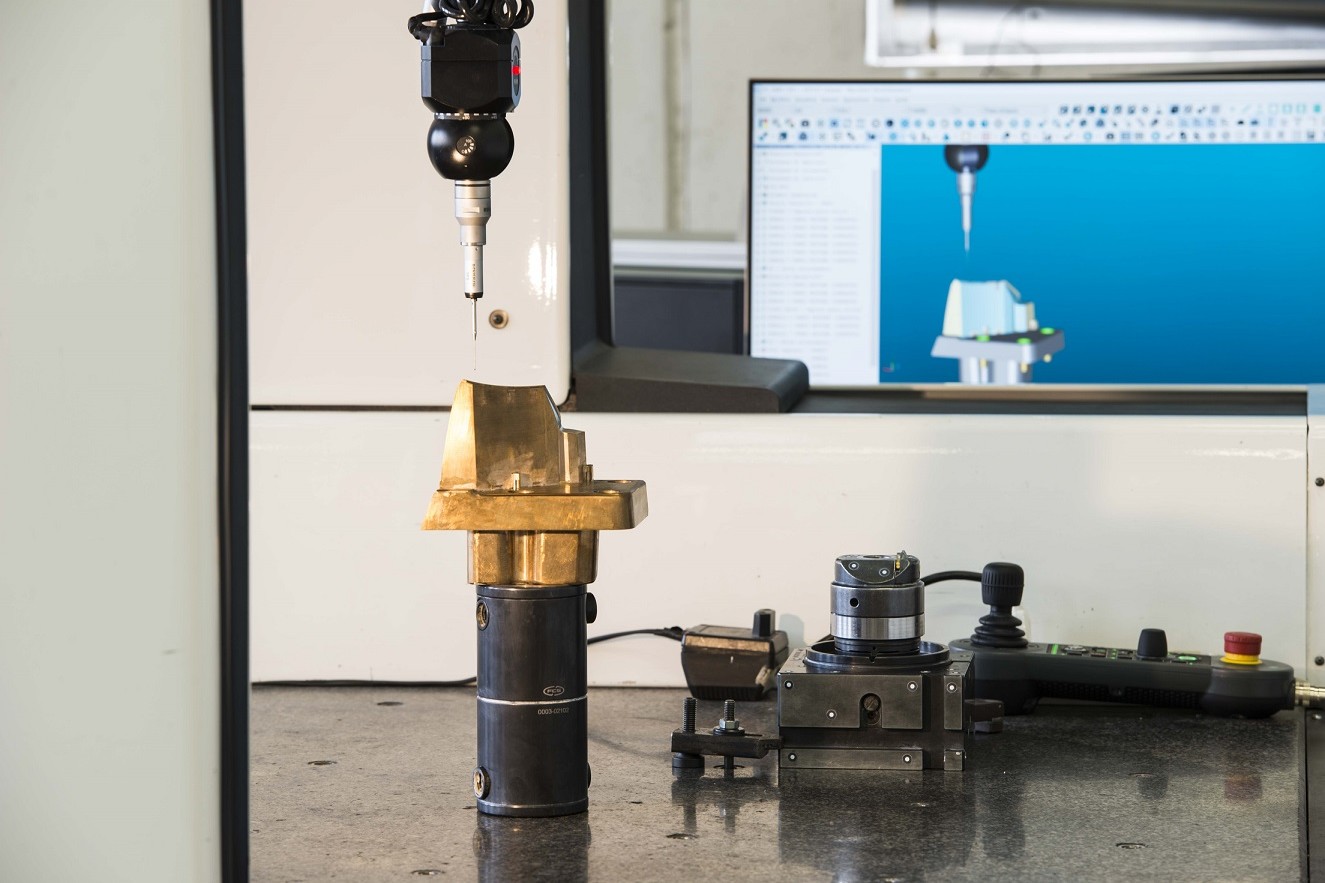

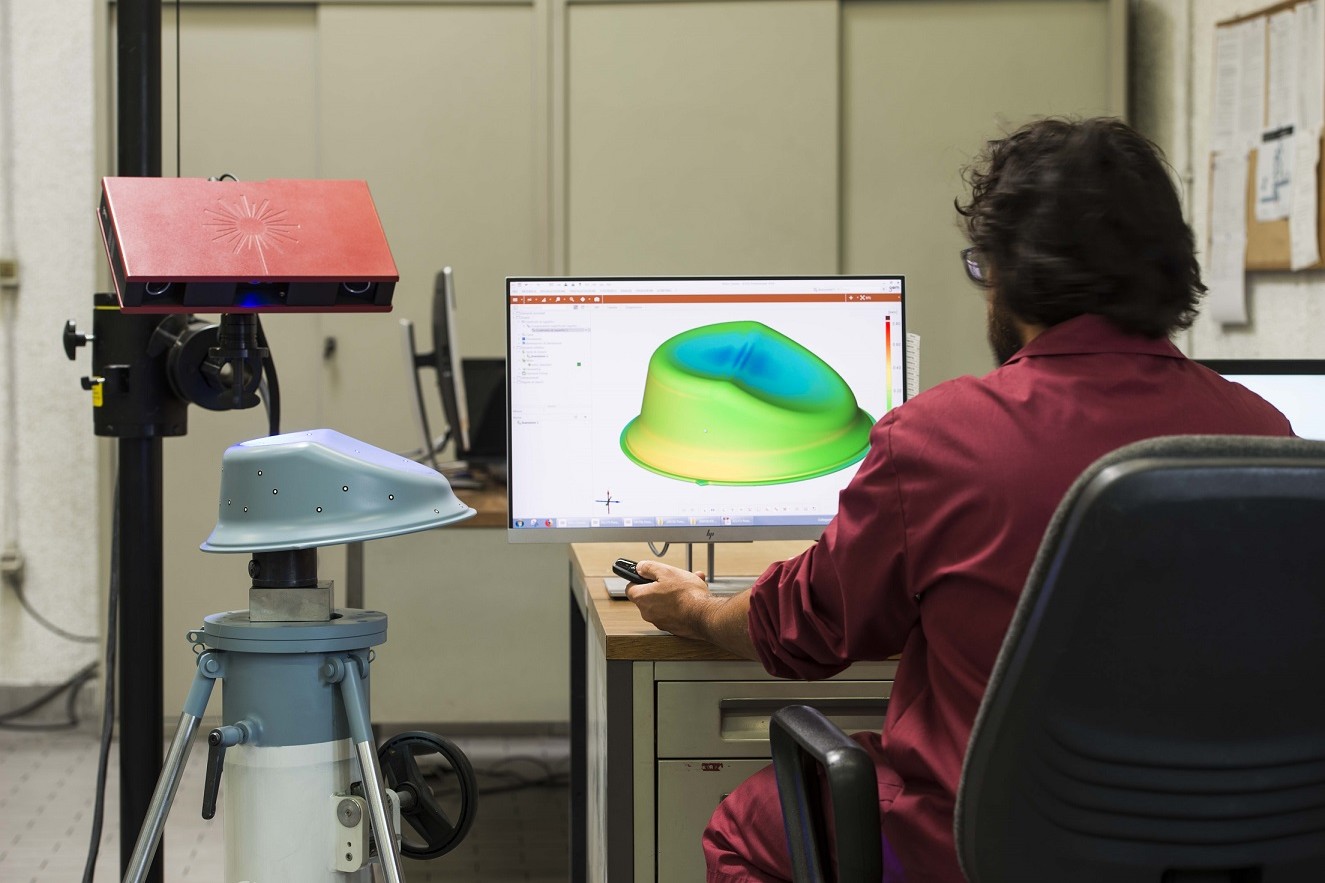

VR Group also has a department dedicated to dimensional control, which is carried out using both contact sensors (CMM DEA 1203) and contactless optical scanners (GOM ATOS CORE) with the advantage in the case of the latter of reducing the time needed to collect data and allowing for the controlled construction of a 3D model.

Customer care

VR group can supply economic and technical evaluation in both production and molds. In addition, Vetrerie Riunite can offer specialised advice in the valuation and management of external foundries.

The process of collaboration together with the client to the smallest detail enables the creation of the mold. Vetrerie Riunite Group also presents a series of finished production pieces to the client to compare and validate any modifications required.

Italiano

Italiano